Introduction

The 20th China International Coal & Mining Technology Exchange and Equipment Exhibition was grandly opened on October 25th in Beijing - China International Exhibition Center (New Venue). With the theme of “Intelligent Leads the Future, Green Shares the Development”, this year's exhibition focuses on new equipment, new technologies and new products in China's coal industry. Among them, Jereh Digital brought Fulima Cloud to the exhibition (Booth No. W4108), bringing smart mine solutions to enterprises and helping the intelligent and green development of mining enterprises.

Two years of grinding a sword Coal industry exchange and cooperation platform

China International Coal & Mining Technology Exchange and Equipment Exhibition is held once every two years. Since it was held in the 1980s, it has gone through 40 years of history, and has become an important place for technology exchange in the domestic and international coal and mining industry, and ranked among the top four mining exhibitions in the world.

With an exhibition area of more than 130,000 square meters and nearly 1,000 exhibitors, this exhibition has played an important platform role in introducing overseas advanced technology and equipment, helping domestic coal machinery and equipment to go out of the country, promoting China's coal scientific and technological progress, and expanding the exchange and integration of peers.

The new engine of mining quality development is empowered by twins

▲Exhibition site, Jieri Digital is explaining the intelligent mine solutions to customers.

The Fulima Cloud, located in Booth W4108, is an industrial internet platform developed by Jereh Digital, which can collect data from the mine environment, equipment, vehicles, materials, personnel, and third-party systems, and provide digital twin services for the management of the entire lifecycle of all elements, so as to realize the digital twin-driven integrated management and control of a single map. Using the concept of smart mine, based on the basic hardware, integrating AI recognition algorithm, integrating third-party systems, breaking through system silos, establishing enterprise user rights management system, data sharing system, and realizing standardized management of business, it forms a top-level service platform integrating digital twin, intelligent decision-making, and intelligent diagnosis.

Production Control Center

Intelligent mine production control center is mainly oriented to production site management, driven by digital twin, restoring the production site through three-dimensional form, integrating data from existing systems, realizing comprehensive monitoring of mine production, equipment, personnel, transportation, environment and energy consumption, and providing real-time alarms for abnormal events to improve management efficiency and reduce safety.

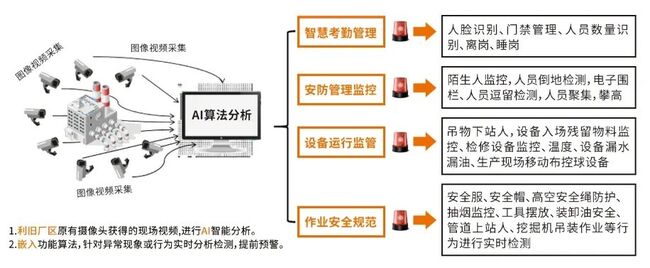

Safety Management Center

The safety control center relies on AI visual analysis in the application of safety production management violation of operation and intelligent warning, including stranger monitoring, smoke and flame (fire) identification, smoking identification, identification of work at height, helmet identification, identification of personnel falling to the ground, leakage of water and oil identification, vehicle parking violations, electronic fences and so on. Abnormal alarm information is pushed to the relevant personnel through the PC and mobile terminal for timely processing, and the realization method of pushing alarm information is clarified in the technical solutions, and intelligent analysis charts can be formed.

Equipment Maintenance Center

The equipment overhaul center is a solution for the whole life cycle management of equipment overhaul process for the situations of equipment item repair, overhaul, temporary failure, maintenance, and so on. It integrates existing equipment and carries out customized development, using digital twin technology to intelligently generate all kinds of reports and realize the management of equipment in one map. At the same time, the center warns the equipment according to the life and running hours of the assembly parts, and assists the management personnel to supervise, analyze, and make decisions on the overhaul management.

Digital Twin-Driven Industrial Internet Platform--Fulima Cloud

Fulima Cloud is a service-oriented manufacturing demonstration platform recognized by the Ministry of Industry and Information Technology of the People's Republic of China, which is committed to effectively assisting enterprises based on manufacturing and integrating services through digital technology, improving their manufacturing efficiency and product service capabilities, reshaping the manufacturing value chain, and promoting the transformation of manufacturing enterprises into service-oriented manufacturing.

The platform includes J3D digital twin development platform, RBI business intelligence development platform, model intelligence lightweight platform and application low-code development platform, supporting Web digital twin, digital decision-making application online development. At the same time, the platform builds an open industrial Internet technology service system, covering a series of products and technology solutions such as Internet of Things, data platform, digital twin application development, algorithm service, etc., to create an industrial Internet industrial ecology with abundant resources, information sharing and win-win cooperation, and to assist enterprises in digital transformation and upgrading of the whole value chain from the three dimensions of digital marketing, digital production, and digital management and control.

The exhibition lasts for 4 days and lasts until October 28th, welcome all customers and friends to visit our booth for guidance and communication!